Deep rolling - Significantly higher component strength through mechanical processing

Brief description

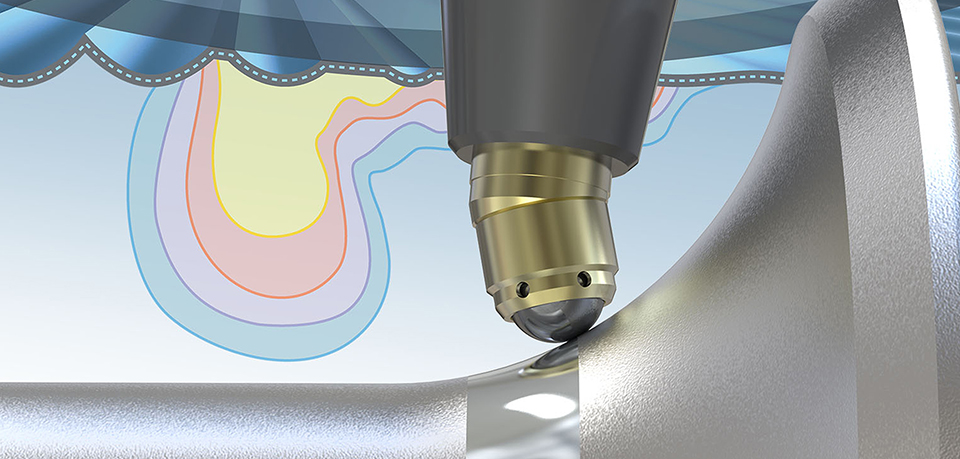

During deep rolling, a roller or rolling ball is pressed onto the surface of a component with a defined force and rolls on the surface. High surface pressure between rolling element and surface results in a deformation of the surface and an influence on the microstructure in the component edge zone.

The deep rolling process allows residual compressive stresses to be introduced into the edge zone to a depth of 1-2 mm, which is significantly deeper than with shot peening. These stress changes counteract crack growth in the mechanical load and thus lead to increased dynamic strength.

In addition, the microstructure is strengthened and there is an increase in hardness on the surface, which can minimize abrasive wear on the component, for example. Microhardness measurements show an increase of 10-30%.

![[Translate to English:] Festwalzen eines Radflansches](https://www.ecoroll.de/fileadmin/_processed_/3/c/csm_AWB_Radflansch_Wheel_hub_a487eef35a.jpg)

![[Translate to English:] Festwalzen eines Lenkhebels](https://www.ecoroll.de/fileadmin/_processed_/e/5/csm_AWB_Lenkhebel_Steering_leaver_26ea079ffb.jpg)

![[Translate to English:] Festwalzen einer Felge (Radiuskontur)](https://www.ecoroll.de/fileadmin/_processed_/b/2/csm_AWB_Felge_Wheel_rim_d6b81016a5.jpg)

![[Translate to English:] Festwalzen einer Dehnschraube](https://www.ecoroll.de/fileadmin/_processed_/f/5/csm_AWB_Dehnschraube_Tension_bold_d887fa8e9d.jpg)

![[Translate to English:] Festwalzen einer hochfesten Schraube](https://www.ecoroll.de/fileadmin/_processed_/0/7/csm_AWB_Hochfeste_Schraube_High-stength_bolt_a1c9e0347e.jpg)

![[Translate to English:] festwalzen einer Eisenbahnachse](https://www.ecoroll.de/fileadmin/_processed_/9/d/csm_AWB_Eisenbahnachse_Railway_axle_01_9e86cff73d.jpg)

![[Translate to English:] Festwalzen eines API-Kegelgewindes](https://www.ecoroll.de/fileadmin/_processed_/7/c/csm_AWB_API-Kegelgewinde_API-thread_pin_abdaacdc11.jpg)