Roller burnishing - With little effort to smooth surfaces

What is special about roller burnishing

Brief description

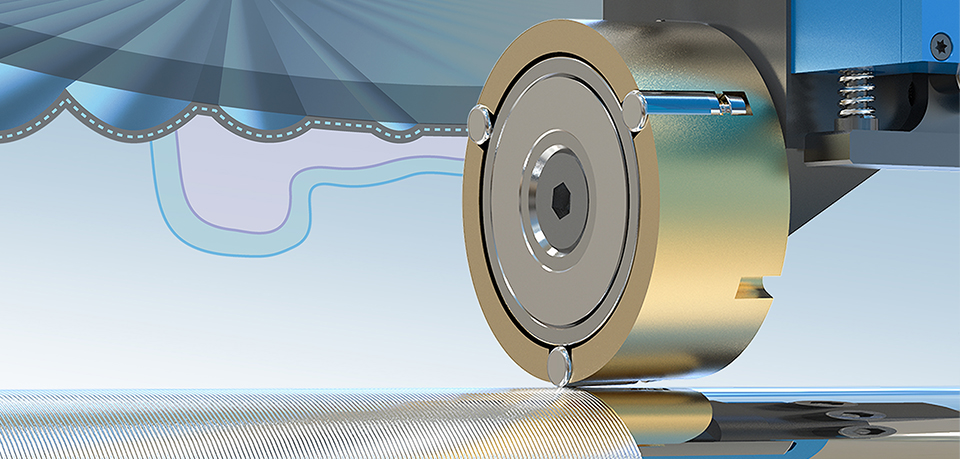

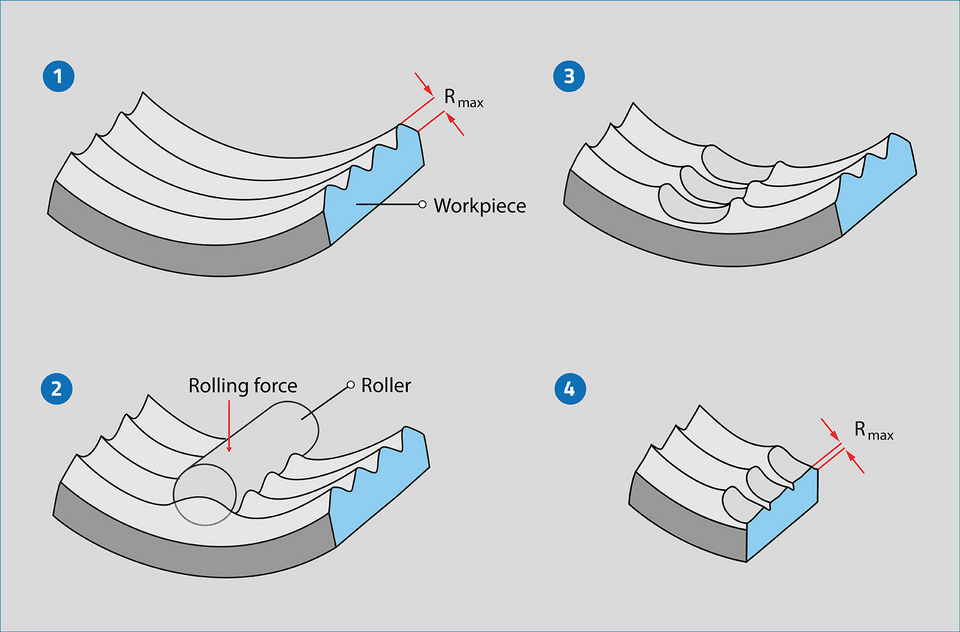

Roller burnishing is all about smoothing the surface of a component by forming the roughness peaks. A roller is pressed onto and guided over a specific surface. This results in plastic deformation of the roughness peaks.

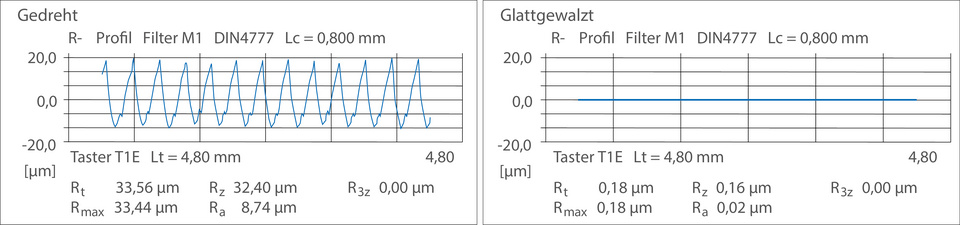

Roller burnishing is a highly productive process in which roughness can be reduced by 50 - 95% compared to pre-machining, depending on the material. A surface quality below Rz = 1µm can easily be achieved with non-hardened steels or aluminium alloys using a roller burnishing process.

The advantage is that the process does not require any material removal and can be used on standard machines directly after machining. Complex polishing or grinding operations can therefore be omitted.

What this means for your component:

Roller burnishing achieves a significantly reduced surface roughness in one setting without material removal and without complex polishing and grinding processes.

Watch the video

How a roller burnishing process works in detail

Roller burnishing is a process for mechanical surface treatment. Machining processes with this purpose are designed to positively influence the surface and edge zone properties of components. They also include shot peening, deep rolling or mechanical hammer peening. What all of this processes have in common, is after machining the surfaces, they are transformed in terms of their shape and properties through a purely mechanical influence.

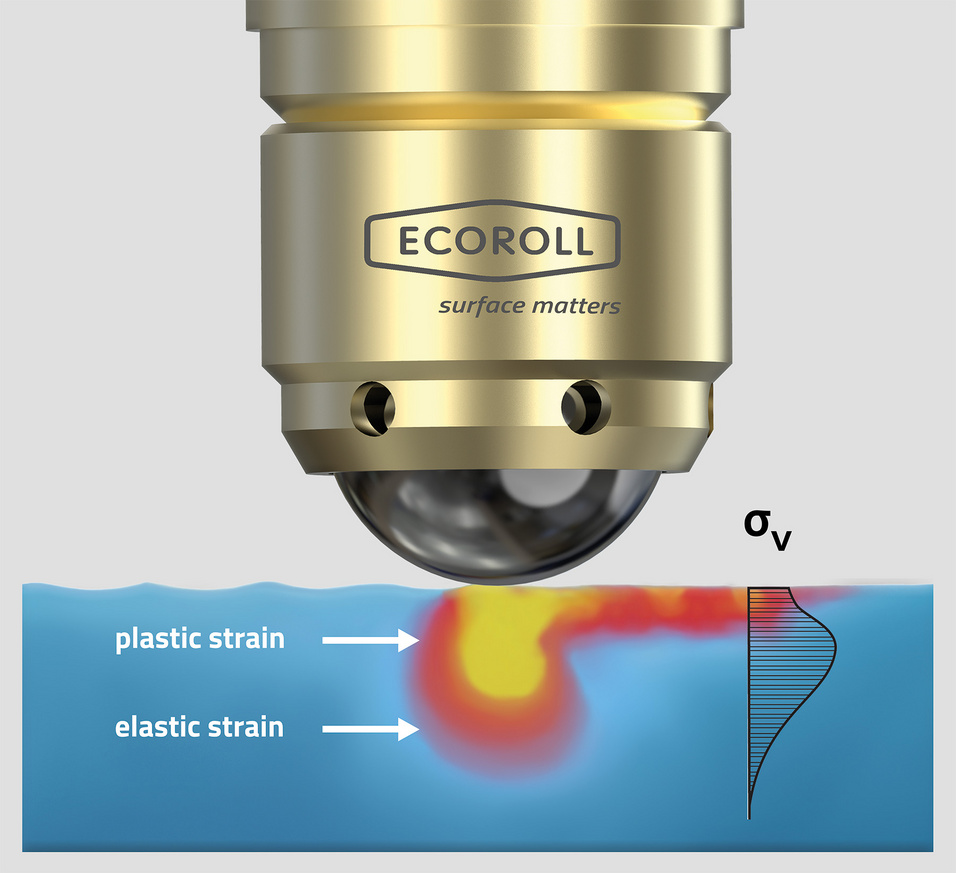

Roller burnishing is closely related to the deep rolling process. In both processes, a defined rolling element is pressed onto the surface with a precisely pre-defined force. Due to the resulting surface pressures, the material is plastically deformed locally on the surface and within the edge zone. Unlike deep rolling, roller burnishing focuses on the improvement of surface roughness, reducing friction between two surfaces. Roller burnishing pursues the same objective as honing, grinding or polishing, but offers many technical and economic advantages. It is therefore a forming process to produce high-quality, smooth surfaces or surfaces with a pre-defined surface structure.

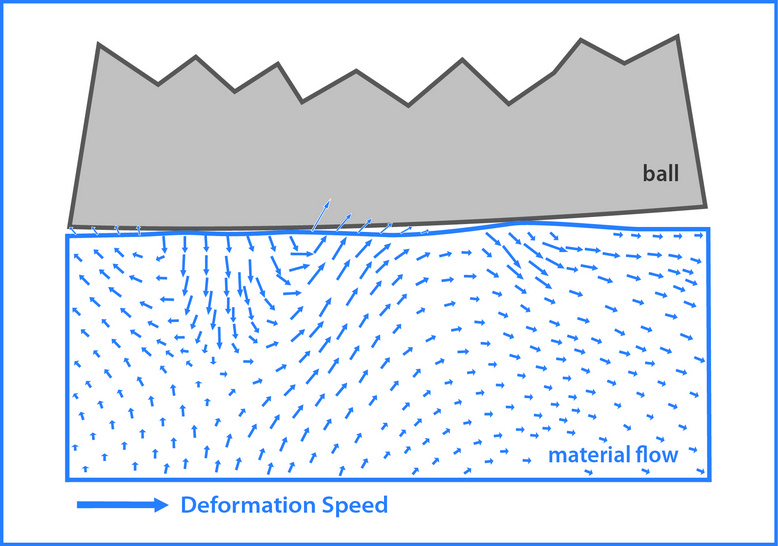

During the forming process, the rolling element first comes into contact with the roughness peaks on the surface. If the occuring stresses (see also Hertzian stress) reach the yield point of the respective material, the roughness peaks are plastically deformed. The material is pressed into the surface. Due to the principle of material conservation during forming, the material now has to flow to another part of the surface. Therefore, the roughness valleys of the surface are filled with material that results in a simultaneous lowering of the roughness peaks and lifting of the roughness valleys which finally leads to a smooth surface.

Due to this forming process, a distinction must be made between roller burnishing soft (<45 HRC) and hard (>45 HRC) materials. With increasing hardness, the material loses its ability to flow under the occurring contact pressures. Based on the definition of the "hardness" property, it is easy to understand that the rolling element cannot penetrate so deeply into the surface when the hardness is high. The process result to be achieved therefore also varies widely with different component hardnesses. If the surface roughness of a soft material can be reduced by 95% compared to the initial roughness, it can only be halved when machining roller bearings with a hardness of 62 HRC, for example.

The process is usually used when the required surface quality cannot be achieved reliably or effectively by a machining process. Due to the forming process, the influence of tool wear on the surface roughness is significantly lower with roller burnishing than with turning or milling. Thus, the process reliability can be significantly increased by roller burnishing, and even smaller tolerance zones can be reliably achieved. For example, if you compare the productivity of finish turning with roller burnishing, it is obvious that because of significantly higher feed rates roller burnishing has the advantage over turning.

Roller-burnished surfaces usually have a roughness of less than Rz = 1 µm or Ra = 0.1 µm. The surface profile is characterized by being smooth and rounded, so that the load-bearing capacity of the surface is increased. In addition to smoothing, the process always leads to a strain hardening of the surface, which is not specifically intended, but a positive side effect.

Roller burnishing can usually be used on lathes and milling machines and, depending on the tool geometry, is suitable for processing different components. ECOROLL AG Werkzeugtechnik has developed various tool types, for example to machine bores as well as plane, conical and also free-form surfaces.

![[Translate to English:] Hartglattwalzen einer Nockenwelle](https://www.ecoroll.de/fileadmin/_processed_/c/a/csm_AWB_Nockenwelle_Camshaft_3cd8d18100.jpg)

![[Translate to English:] Glattwalzen eines Kegelrades](https://www.ecoroll.de/fileadmin/_processed_/e/2/csm_AWB_Kegelrad_Beavel_gear_8531632c4a.jpg)

![[Translate to English:] Glattwalzen einer Führungshülse](https://www.ecoroll.de/fileadmin/_processed_/4/a/csm_AWB_Fuehrungshuelse_Guide_sleeve_c2d460111d.jpg)

![[Translate to English:] Glattwalzen einer Bremsscheibe](https://www.ecoroll.de/fileadmin/_processed_/3/d/csm_AWB_Breamsscheibe_Brake_disc_ceb1b26611.jpg)

![[Translate to English:] Hartglattwalzen eines Schaufelschwenklagers (außen)](https://www.ecoroll.de/fileadmin/_processed_/2/2/csm_AWB_Schaufelschwenklager_Sweavel_bearing_01_3e2fb89a75.jpg)

![[Translate to English:] Glattwalzen einer Kolbenstange](https://www.ecoroll.de/fileadmin/_processed_/0/c/csm_AWB_Kolbenstange_Piston_rod_e486ea6ec0.jpg)

![[Translate to English:] Glattwalzen eines PET-Formkerns](https://www.ecoroll.de/fileadmin/_processed_/5/4/csm_AWB_PET-Formkern_PET-Mold_6957122534.jpg)

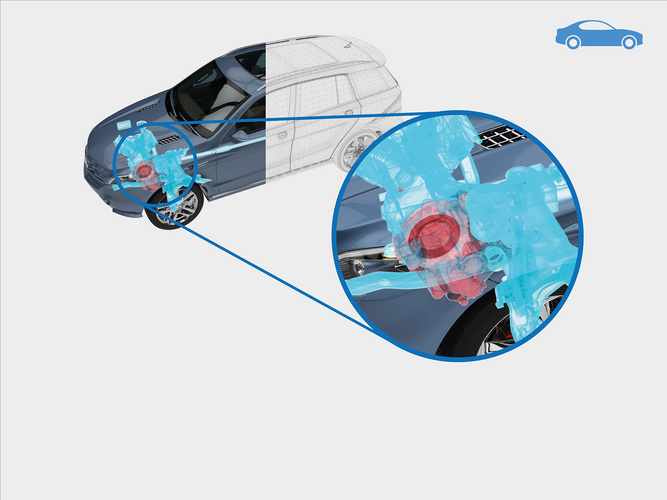

![[Translate to English:] Glattwalzen eines Kugelgelenks](https://www.ecoroll.de/fileadmin/_processed_/d/6/csm_AWB_Kugelgelenk_Ball_joint_934c1cc3cd.jpg)