Efficient machining of bores with highest accuracy

Bores are an elementary design element of mechanical components. They take on many leading or positioning tasks and are therefore obviously subject to different requirements. These can be requirements in terms of geometrical accuracy (gradient, roundness or dimension) or also in terms of hardness and surface properties.

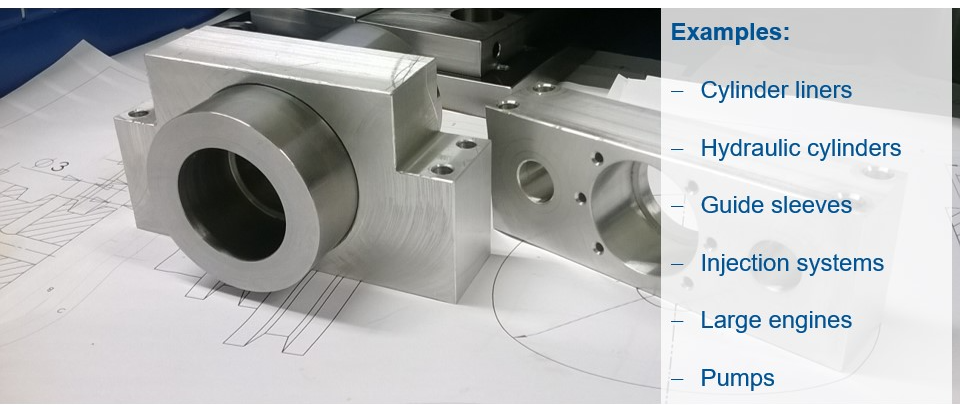

Well-known examples of bores with particularly high surface requirements are hydraulic cylinders, guide sleeves or, the classic from the automobile, cylinder running surfaces. All of these bores have to meet high demands in regard to shape and, above all, surface quality. Cylinder running surfaces are finished on special machines through a honing process. In this process, a specific surface topography is created in order to minimize friction during engine operation.

At the same time, however, bores always weaken the mechanical structure which can initiate cracking under dynamic loading. A prominent example of this phenomenon is a cooling bore in crankshafts. In this case, the torsional load can lead to cracking at the bore entrance.

One means of optimizing the properties of a bore is mechanical surface treatment. Roller burnishing, deep rolling or shot peening can be used to optimize the surface and edge zone properties in a targeted manner. As a result, roughness can be effectively reduced in production or residual compressive stresses can be introduced to increase the service life under dynamic load.

Tools for roller burnishing and deep rolling of bores

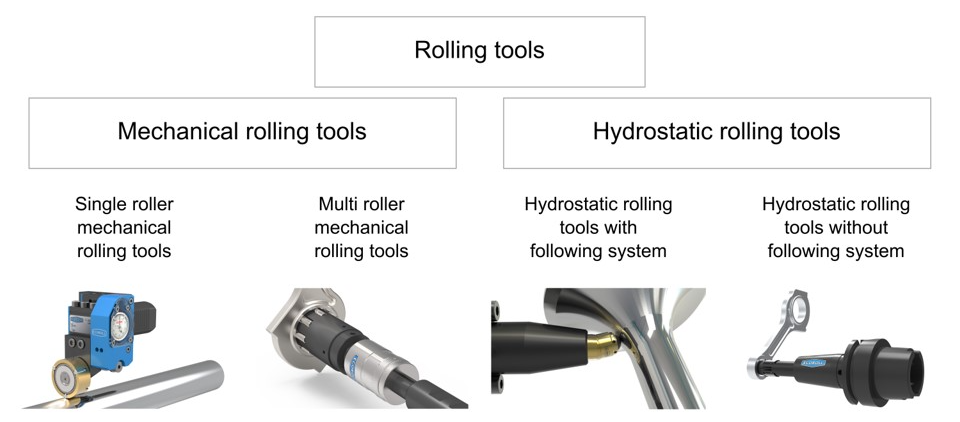

For roller burnishing and deep rolling, there are a wide variety of tool concepts for processing bores reliably and even more important productively. Basically, a distinction is made between mechanical and hydrostatic rolling tools. In bore machining, the classic approach would be roller burnishing with mechanical multi-roller tools. However, due to the more precise process control, hydrostatic tools are better suited for hardening the component in a targeted manner.

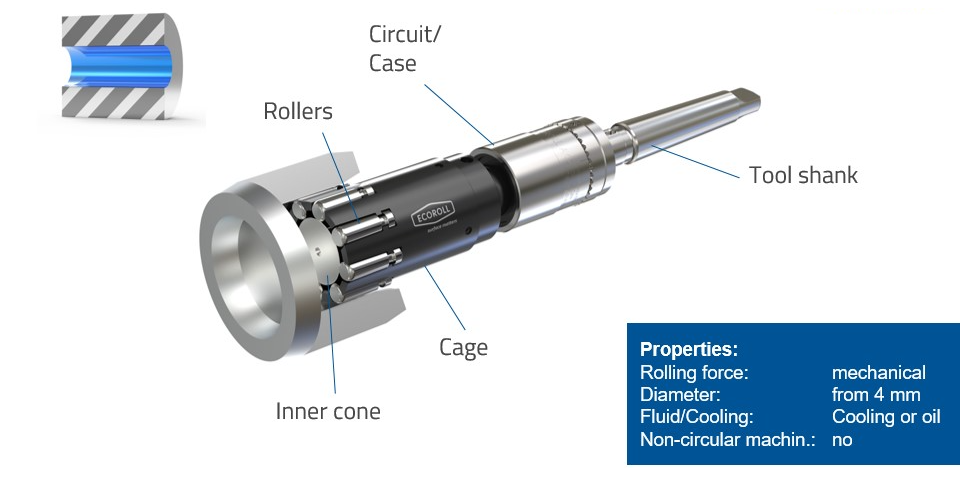

Mechanical multi-roller tools

This tool type is characterized by a very simple design. The operating principle is basically based on a rolling bearing. The tool consists of a clamping unit, a housing, an inner cone, a cage and the rollers arranged on the circumference. The cone corresponds to the inner ring of a roller bearing. The rollers are evenly distributed over the circumference of the tool and are held in position and are guided by the cage.

Such a tool is always designed to be diameter-specific. An adjustment device in the housing allows the inner cone to be moved in axial direction. As a result, the centrifugal circle diameter of the rollers changes, and the rolling diameter becomes smaller or larger. This means that the machining diameter of the tool can be minimally adjusted in relation to the designed diameter.

The degree of material forming is determined by the preset oversize to the bore. For the process, the machine operator adjusts the oversize at the tool. The tool is then rotated axially into the bore. Kinematically, the process corresponds to a drilling process. However, by using several special rollers, significantly higher feed rates per revolution can be set. It is possible to drive into the bore with feed rates of up to 3 mm per revolution.

Another advantage of this tool type is that several rollers are engaged and thus the mechanical load of the rolling process is compensated. All radial forces are absorbed in the cone and cancel each other out. The resulting axial force in the feed direction is minimal due to the small angle of the cone and does not pose a challenge to machine tools.

Since roller burnishing does not require such close process monitoring and the process result responds less strongly to force variations, this tool is well suited for the process. Of course, diameter fluctuations during pre-processing have a direct effect on the rolling force, which influences the formation of residual compressive stresses or solidified microstructures.

As the process control does not have to be so strictly controlled with roller burnishing and the process result reacts less strongly to force fluctuations, this tool is well suited to the process. Diameter fluctuations during pre-processing naturally have a direct effect on the rolling force, which influences the formation of residual compressive stresses or hardened microstructures. However, the resulting roughness is less affected by the rolling force in this area.

Hydrostatic tools for bore machining

In contrast to multi-roller roller burnishing tools, hydrostatic tools are very suitable for deep rolling. With this type of tool, the rolling ball is pressed onto the surface by a hydraulic medium. This means that the force is only dependent on the rolling pressure, but not on the diameter of the pre-machining.

Here too, there are tools specially designed for bore machining. These also consist of an individually designed clamping device for the machine tool and a roller head with two opposing roller balls. The roller balls are fixed in the roller head via claws. The tool can also be equipped with a flushing nozzle. This nozzle uses the hydraulic medium and the rolling pressure to clean the surface before rolling so that no particles, chips or something similar are rolled into the surface.

The rolling pressure for hydrostatic tools can be up to 600 bar. In bore machining, the ball holder is the determining part, so that the maximum rolling pressure can vary from tool to tool. After all, the rolling ball must always be securely fixed in the ball holder and must not be pushed beyond the applied pressure.

These tools are also designed for a specific diameter. However, the bore does not have to be exactly round. Oval bores or so-called trumpet shapes can also be machined. The ball has a small amount of play in the ball holder and therefore always machines the surface with the same rolling force via the rolling pressure.

The process kinematics here also correspond to those of a classic drilling process. With the tool or workpiece rotating, the tool moves into the component at a defined feed rate. Compared to the mechanical multi-roller tool, however, only significantly lower feed rates can be used here. The contact surface between the ball and the bore is simply much smaller, so that standard feed rates in the range of 0.1 - 0.3 mm are used.

Roller burnishing and deep rolling processes improve the quality of bores through an efficient manufacturing process

The use of mechanical or hydrostatic tools for bore machining offers an excellent opportunity to specifically improve the quality of a bore. The process is able to replace complex grinding or reaming processes and thus optimize production in terms of costs.