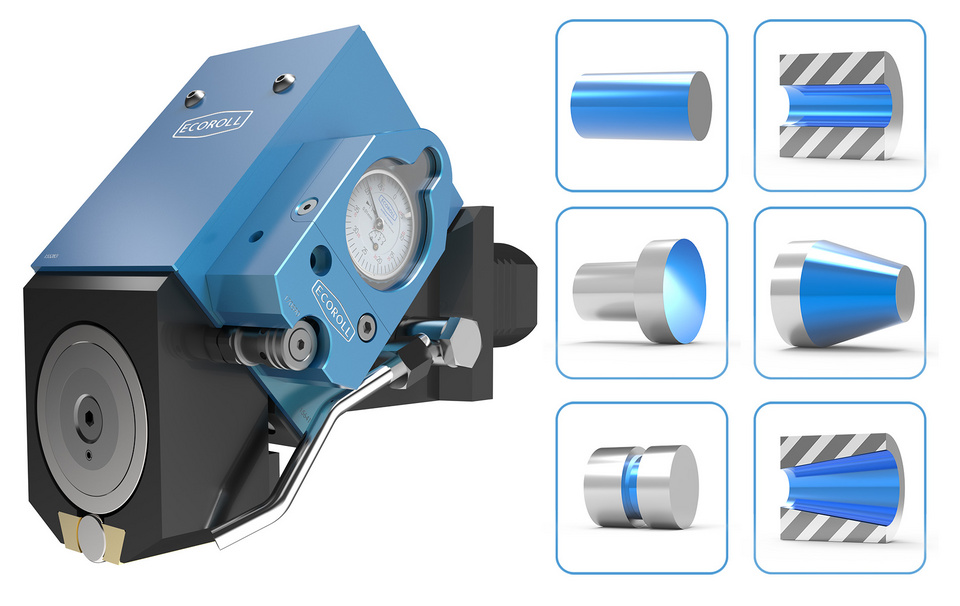

EG14: External surfaces, cylindrical and conical bores

Characteristics

- Machining of external cylindrical and conical surfaces, external or internal plane surfaces, as well as cylindrical and conical bores (a special type is required for machining conical surfaces).

- Can be used on CNC or conventional lathes

- Machining in a chuck

- Attainable surface finish Rz < 1 micron (Ra = 0.2 micron)

- Processing of all metallic materials with a tensile strength of up to 1400 N/mm2 and a maximum hardness of HRC = 45

- Can be used as right or left-handed tool

- Both directions of rotation possible

Advantages

- Short primary processing time

- Elimination of set-up times and downtimes

- No occurrence of dust and slurry

- Only nominal lubrication required (oil or emulsion)

- Roller head guidance without play and low-friction

- Stepless roller pressure adjustment using infeed support

- Consistent and controlled machining results through measurement of roller pressure

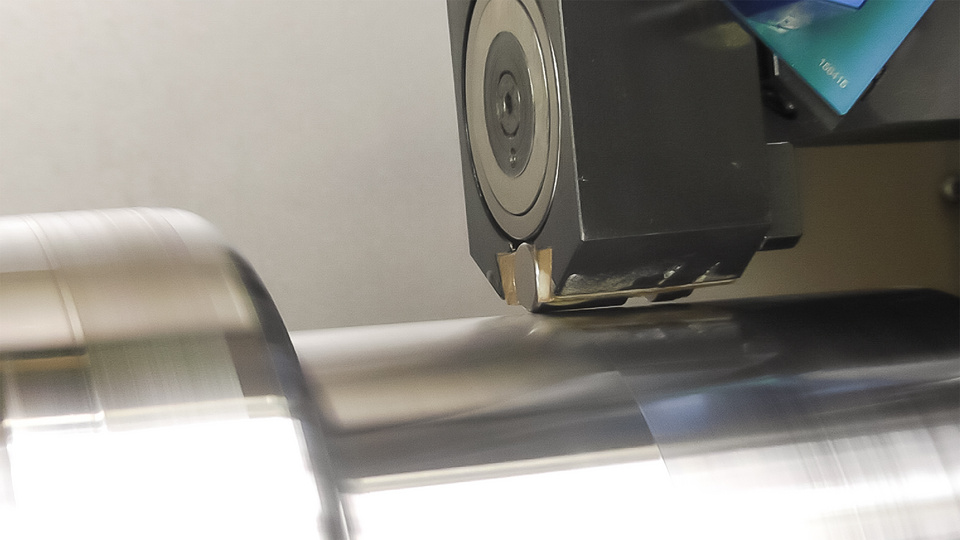

- Face of the roller free, thus enabling machining close to shoulders and other edges

- Simple replacement of wear parts

Basic construction

- Type EG14 single roller burnishing tools consist of a tool body equipped with a tool shank, a spring assembly that allows the roller head to move with no play and very low friction.

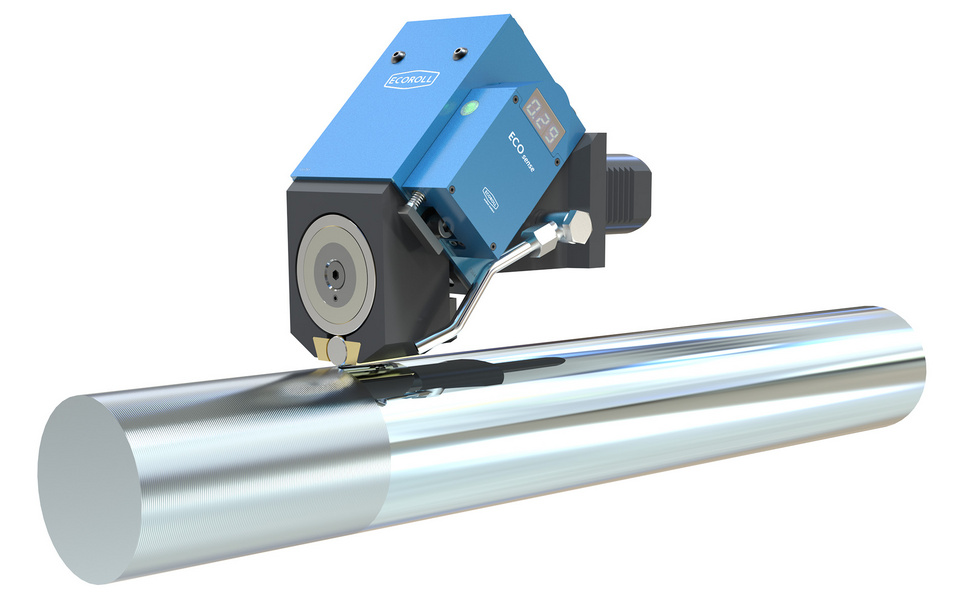

- The standard version contains a dial indicator for indirect indication of the spring force. As an option, the tools can be equipped with ECOsense process monitoring for external display of the spring force.

- The roller head is attached to the flexible, spring-loaded section of the tool body. It consists of a cage, which contains and guides the burnishing roller, and a support roller with a large-scale needle bearing.

- Tool design includes fixed roller clearance angle α.