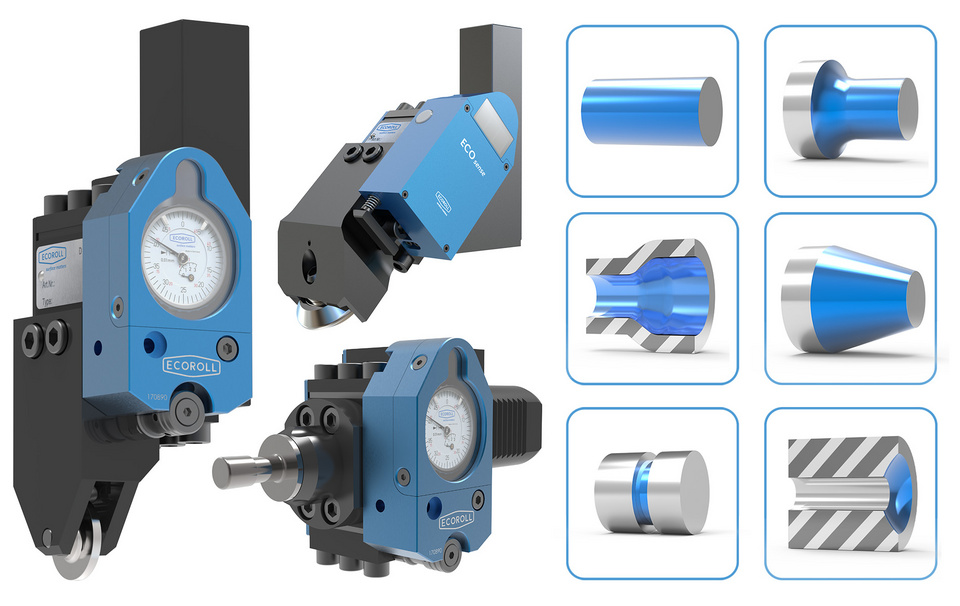

EG5-1-25, EG5-08F, EG5-40M: Contours, concave fillets, groove bed machining and short bores

Characteristics

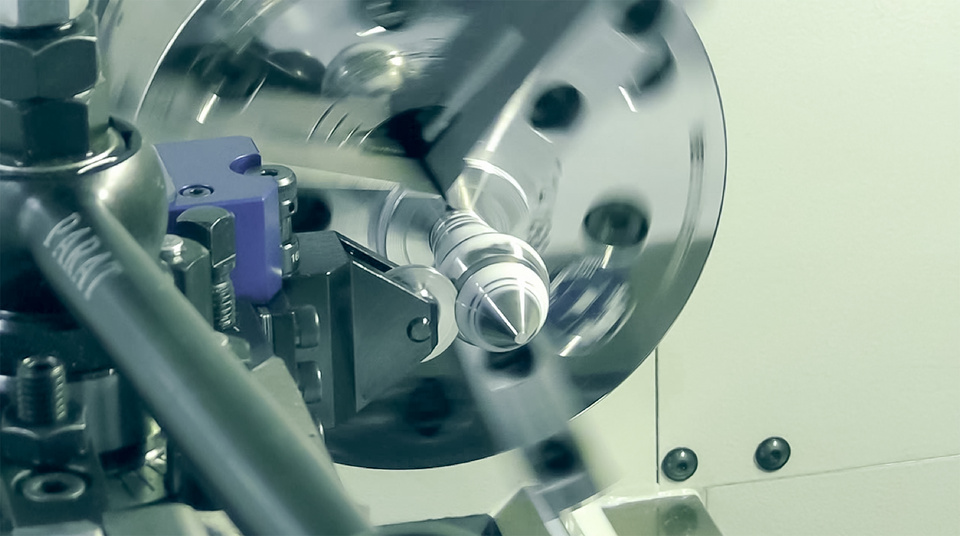

- Can be used on CNC or conventional lathes.

- Machining in a chuck.

- Attainable surface finish Rz < 1 micron (Ra = 0.2 micron).

- Processing of all metallic materials with a tensile strength of 1400 N/mm2 and a maximum hardness of HRC = 45.

- Universally useable modular system.

- Can be used as right or left-handed tool.

- Both directions of rotation possible.

Advantages

- Short cycle time.

- Eliminates set-up and auxiliary processing time.

- No dust or grinding residue.

- Minimal lubrication required (oil or emulsion).

- Accurately measured burnishing force ensures.

- Consistent, high quality results.

- Unrestricted roller face makes roller burnishing of shoulders and other edges possible.

- Easy to change wear parts.

Basic construction

- Type EG5 single roller burnishing tools consist of a tool body equipped with a tool shank, a spring assembly that allows the roller head to move with no play and very low friction, and a gauge that indicates the burnishing force as measured by spring deflection.

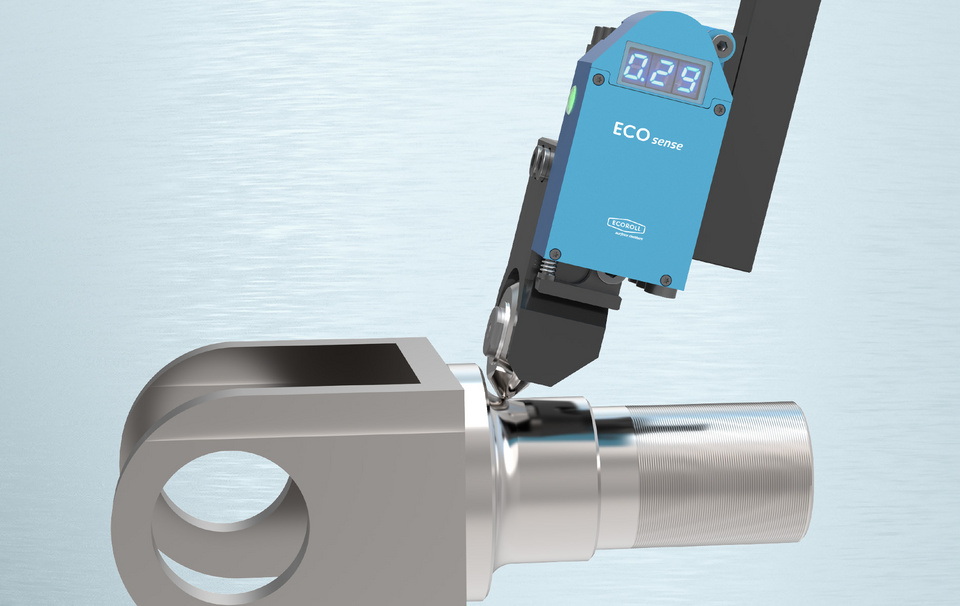

- An optional device transmits the values by cable or wireless signal to an external indicator.

- The roller head is attached to the flexible, spring-loaded section of the tool body. It consists of a cage, which contains and guides the burnishing roller, and a support roller with a large-scale needle bearing.

- The cage also contains two spare rollers.

- Tool design includes fixed roller clearance angle α.

EG5-08F

Roller burnishes groove flanks on the face or circumference and bores.

- With diameters of 8.5 mm and larger

- Max. rolling depth: 20 mm for diameters of 8.5 mm and larger

- Tool body’s spring assembly positioned parallel to workpiece surface.

- Floating roller head attached to the tool body’s flexible, spring-loaded section.

EG5-40M

- Machining cylinders with subsequent radius to the plane surface.

- Suitable for low and medium strength materials.

- Extremely narrow roller.

- Tool body’s spring assembly positioned parallel to workpiece surface.

- Roller head attached to the tool body’s flexible, spring-loaded section.

- Extremely narrow roller with an integrated four-point bearing.

EG5-40M-45°: Roller burnishes cylindrical surfaces with connecting fillet radii up to the workpiece face.

- Tool body’s spring assembly positioned at a 45° angle to workpiece surface.