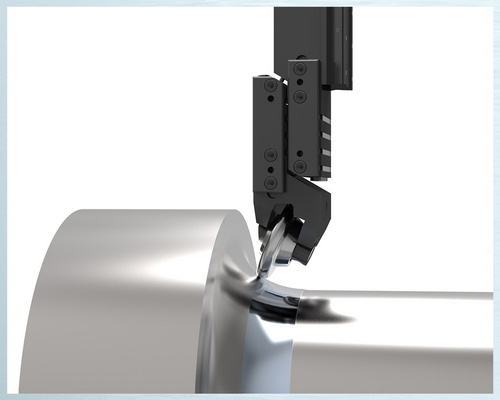

FAK: Deep rolling of fillets

Characteristics

- Deep rolls fillets with the plunge-in process.

- Deep rolls contours or large fillets with the in-feed process.

- Roller unit includes axial/radial bearings for the in-feed process.

- Rolling force monitored by a dial gauge or sensor.

Advantages

- For use with CNC-controlled or conventional lathes.

- Complete processing in one setting.

- Symmetrical construction allows either right- or left-hand operation.

- Rotates in either direction.

Basic construction

- Type FAK deep rolling tools consist of a tool body equipped with a shank, a spring assembly that allows the roller head to move with no play and very low friction.

- The standard version contains a dial indicator for indirect indication of the spring force. As an option, the tools can be equipped with ECOsense process monitoring for external display of the spring force.

- The roller head is attached to the flexible, spring-loaded section of the tool body.

- The flexible roller holder moves in response to the radial or axial rolling forces on either side of the tool. The roller holder contains a finely machined, hardened roller with two tapered roller bearings.