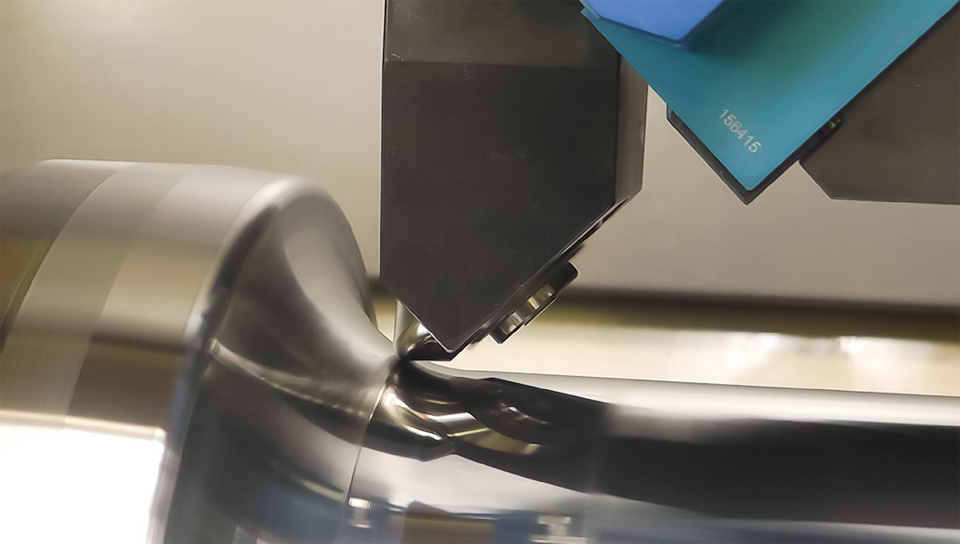

EG45: Concave fillets and contours

Characteristics

All tools

- For use on CNC or conventional lathes with hydraulic contouring equipment

- Machining in a chuck

- Attainable surface finish Rz < 1 micron (Ra = 0.2 micron)

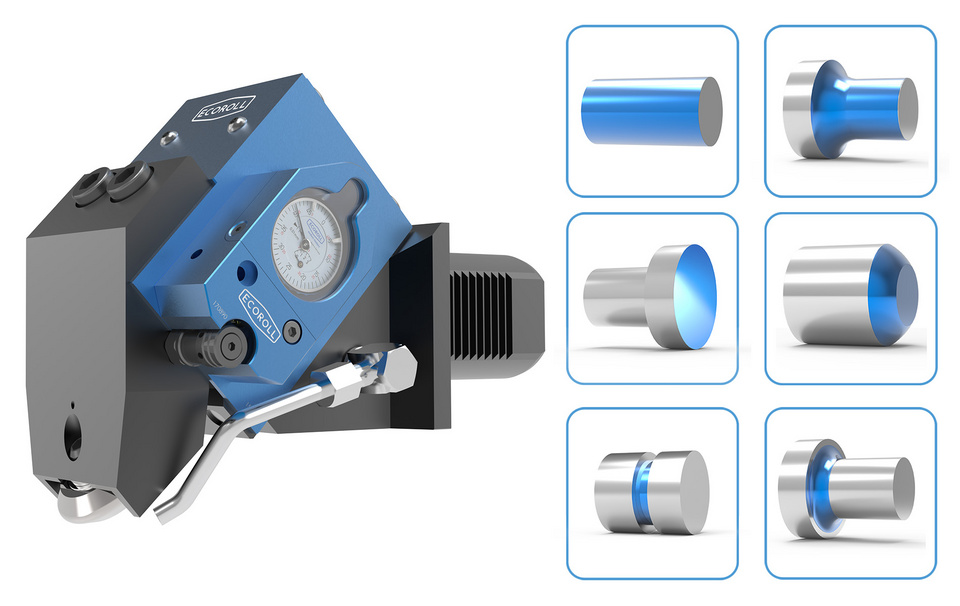

EG45-40M

- Machining cylinders with subsequent radius to the plane surface

- Suitable for low and medium strength materials

- Extremely narrow roller

EG45-55TS

- Machining of cylinders or plane surfaces with subsequent transitional radii of up to 75°

- High roller pressure, suitable for high-strength materials

- Equipped with cantilever roller arrangement

EG45-45F

- Tool with cantilever-mounted shaped roller of special design for machining convex and concave shapes by plunge or motion technique

- Equipped with cantilever roller arrangement

3D-View EG45-40M

3D-View EG45-55TS

Advantages

- Elimination of microscopic grooves and simultaneous introduction of residual compressive stress

- Short primary processing time

- Elimination of set-up times and downtimes

- No occurrence of dust and slurry

- Only nominal lubrication required (oil or emulsion)

- Roller head guidance without play and low-friction

- Stepless adjustment of roller pressure

- Consistent and controlled machining results through measurement of roller pressure

- Simple replacement of wear parts

Basic construction

- Type EG45 single roller burnishing tools consist of a tool body equipped with a tool shank, a spring assembly that allows the roller head to move with no play and very low friction.

- The standard version contains a dial indicator for indirect indication of the spring force. As an option, the tools can be equipped with ECOsense process monitoring for external display of the spring force.

- The roller head is attached to the flexible, spring-loaded section of the tool body.

- EG45-55TS and -45F are equipped with floating rollers.

- EG45-40M comes with a smaller roller. Because of its structure, EG45-40M has a lower load capacity.